Tools & molds manufacturing by ECOM

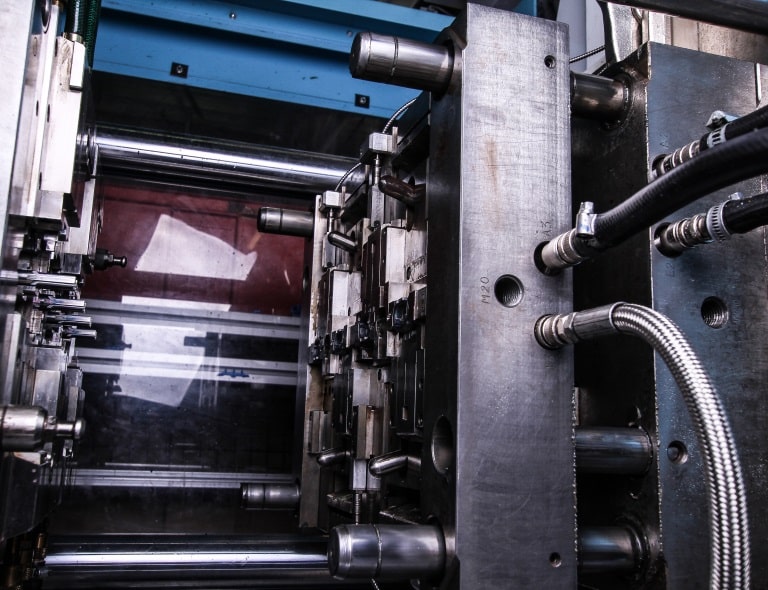

Next door to the injection molding plant, ECOM designs and manufactures molds, dedicated to the polymer’s parts.

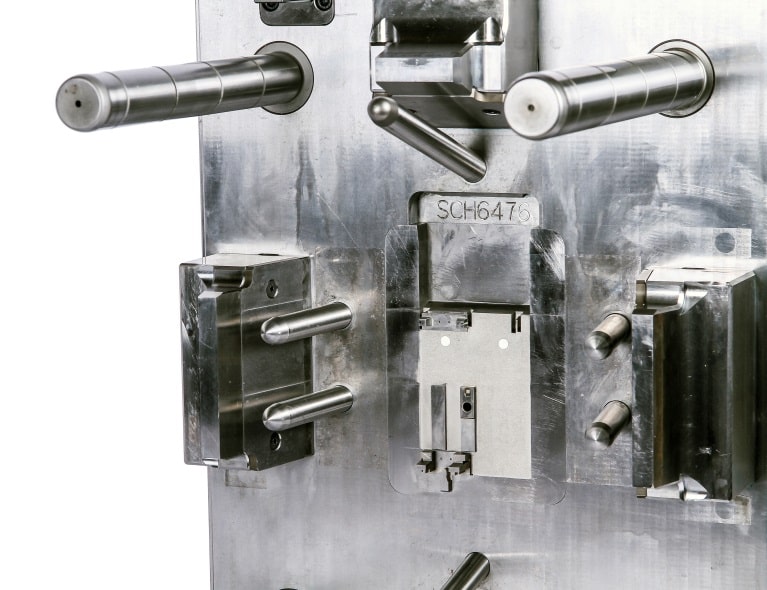

Thanks to MICROPLAST’s expertise in plastic injection molding, the design and realization of your molds are optimized, according to use, small series, or large series.

Indeed, it is a decisive know-how in the industrialization strategy at your disposal. Depending on the market and your technical requirements, MICROPLAST offers you in-house molds 3,000,000 shots guaranteed or managing your project, in “low-cost” and “best cost” countries with finishing and fine-tuning development in the ECOM workshop.

Design of your molds ECOM

Next door to the injection molding plant, ECOM designs and manufactures molds, dedicated to the polymer’s parts.

Thanks to MICROPLAST’s expertise in plastic injection molding, the design and realization of your molds are optimized, according to use, small series, or large series.

Indeed, it is a decisive know-how in the industrialization strategy at your disposal. Depending on the market and your technical requirements, MICROPLAST offers you in-house molds 3,000,000 shots guaranteed or managing your project, in “low-cost” and “best cost” countries with finishing and fine-tuning development in the ECOM workshop.

Mold transfers & maintenance

In addition to the design and manufacturing of your molds, ECOM takes care of your existing molds for a tune-up or repair.

Whatever the origin of the tools, we offer the best solutions to each situation.

ECOM takes care of the various maintenance operations for you.

This integrated know-how provides an important guarantee of quality, efficiency, and confidentiality.

ECOM’s equipment

ECOM has a late state of art workshop:

- 1 HSM machining center (Okuma)

- 2 NCM (Hermlé)

- 4 EDMs by sinking with charger 28 electrodes

- 5 wire EDMs

- 1 EDM for quick drilling

- 5 grinding machines with Optidress

- 1 welding station per Laser

- 1 conventional machine park

Kind of molds realized by ECOM?

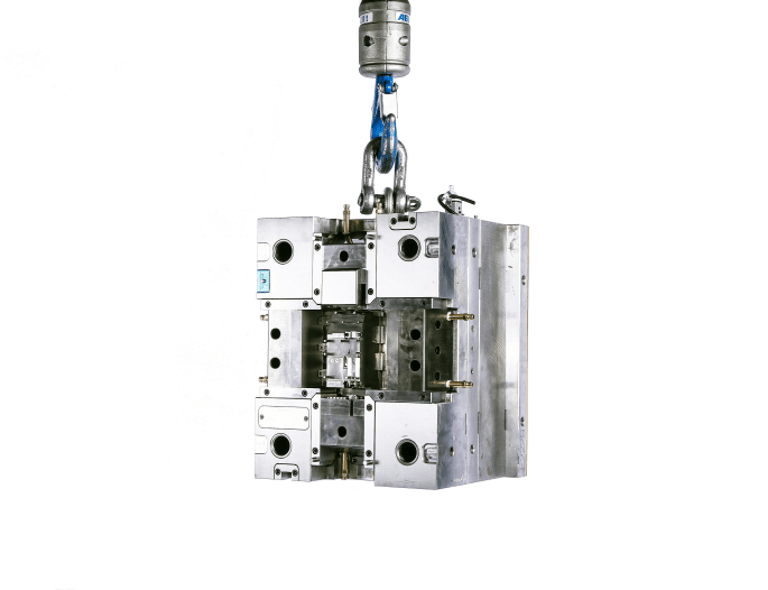

ECOM designs and manufactures high-tech molds:

- modular molds (versioning, stake molds)

- molds equipped with hot runners

- multicavity molds (e.g. 96 connector cavities)

- continuous overmolding mold for tape contacts

- 2 k-materials mold

ECOM provides a full service for tooling: mold transfers, mold modifications, reception of “best cost” or “low-cost” molds and adapted maintenance plans.